| FILETYPE=SNAPSHOT

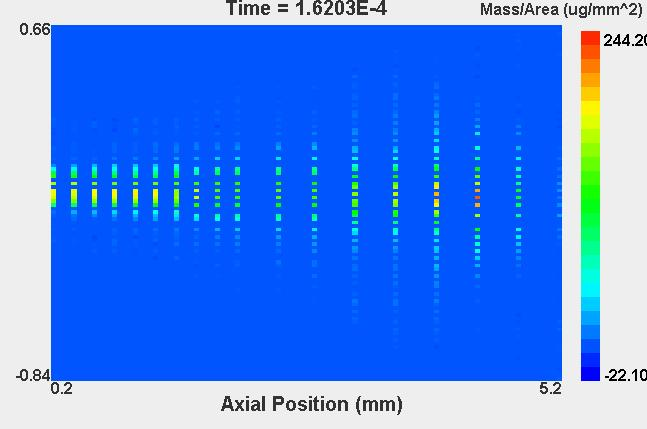

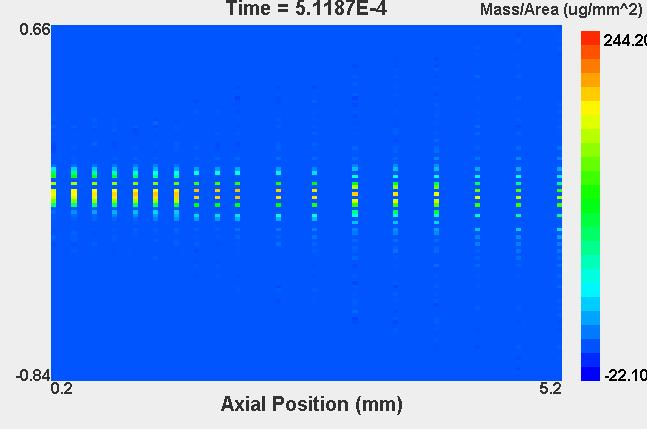

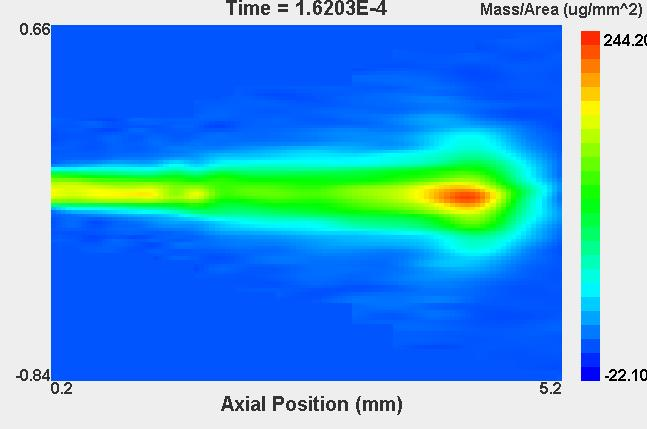

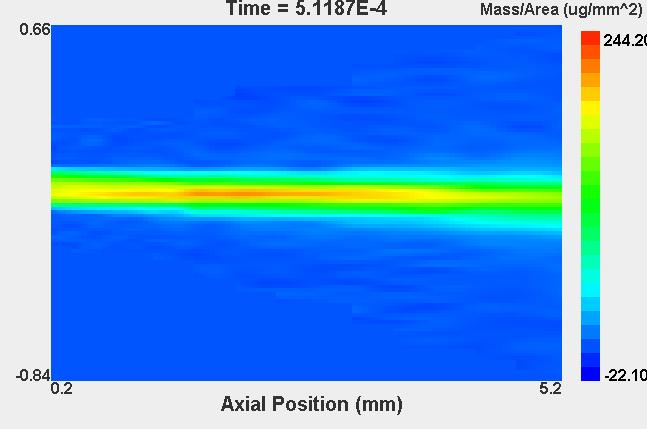

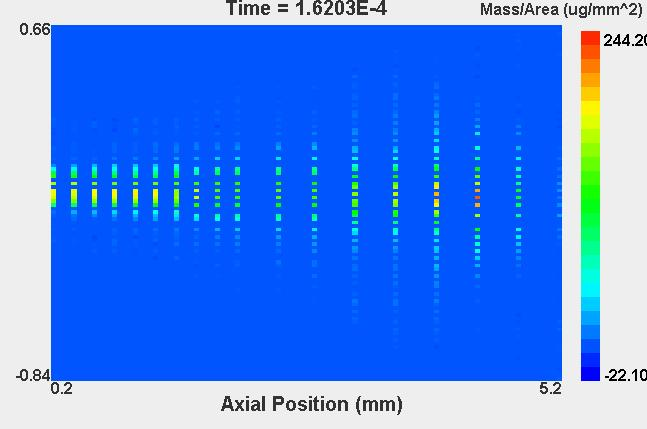

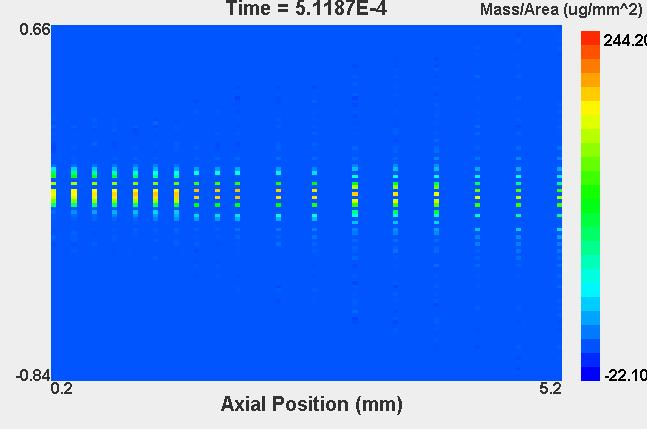

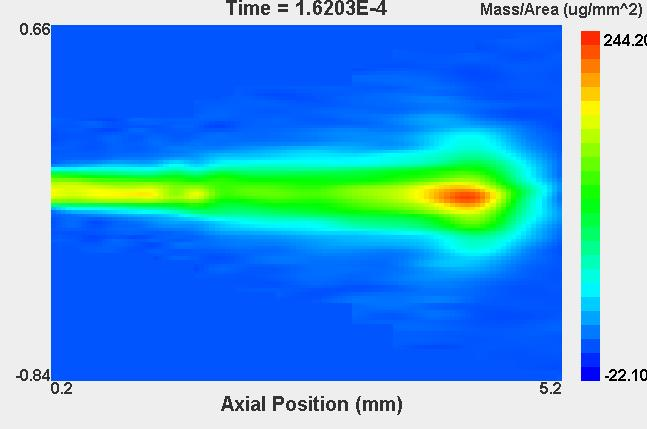

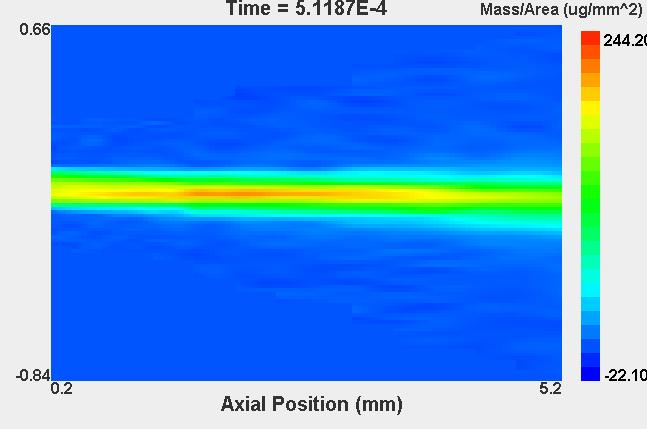

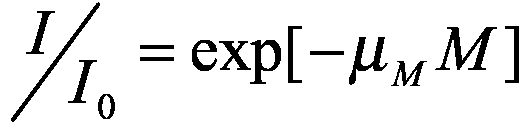

UNITS=MICROGRAMS/MM^2 MUMASS=0.002415 |

|||||

| #x_position |

y_position |

time(1) | time(2) | ... | time(N) |

| x(coordinate1) | y(coordinate1) | mass(t1) | mass(t2) | ... | mass(tN) |

| x(coordinate2) | y(coordinate2) | mass(t1) | mass(t2) | ... | mass(tN) |

| ... | ... |

... |

... |

... |

... |

| x(coordinateM) | y(coordinateM) | mass(t1) | mass(t2) | ... | mass(tN) |

| Window |

Effective

Field of View |

Pressure Range |

| 38 x 122 |

35 mm x 115 mm |

1 bar absolute |

| 3 x 22 |

2.5 mm x 18 mm |

1-35 bar absolute |

| 12 x 30 |

11 mm x 26 mm |

1-5 bar absolute |